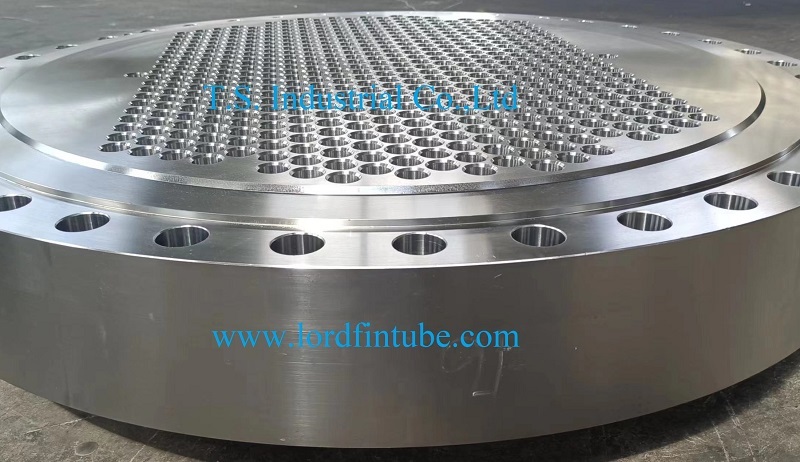

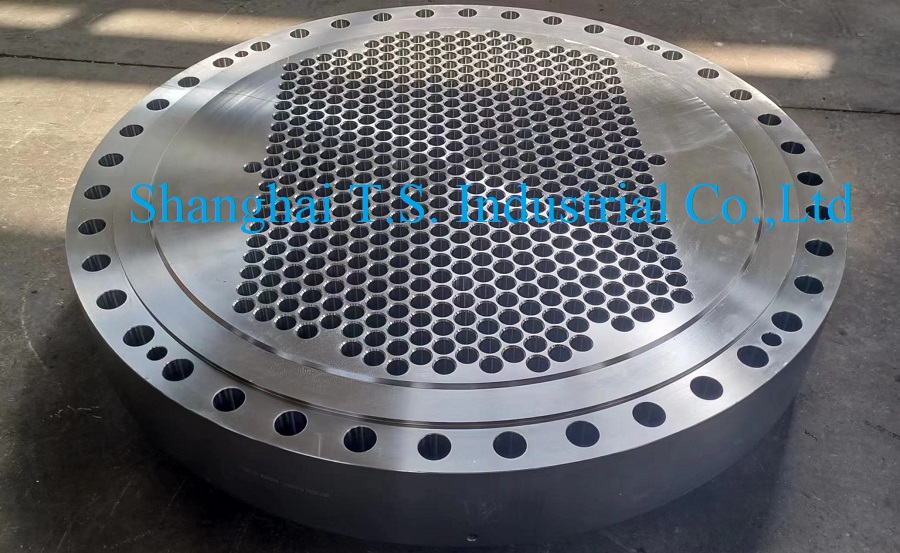

Floating tube sheet|Floating tubesheet

VIEW MORE+- The structure of shell and tube heat exchangers and Main parts

- LL-Foot Finned Tube VS L-Foot Finned Tube

- Whats the process type for helical tube coils?

- Duplex stainless steel knowledge

- Introduce ASTM A209/ASME SA209 T1 Boiler Tube

- Fin-type radiators function and application

- What are the Effects of Heat-Affected Zones in Finned Tubes?

- What Causes Heat-Affected Zones?

- What is the Heat Affected Zone (HAZ) in finned tubes?

- Preheating Before Welding-Method to Prevent Welding Cracks

Naval brass tube sheet|Naval brass tubesheet

Naval brass tube sheet is a type of brass alloy that is commonly used in marine applications due to its excellent corrosion resistance in seawater, which is a component used in heat exchangers.

What is naval brass tube sheet?

A naval brass tube sheet is a component used in heat exchangers and other industrial applications that involve the transfer of heat between fluids. It is typically made from naval brass, which is a type of brass alloy that contains a high percentage of copper (typically around 60-70%), along with zinc and sometimes small amounts of other elements like tin and lead.

The tube sheet serves as a support structure for a bundle of tubes, and its primary function is to hold the tubes in place while providing a sealed partition between the two fluid streams in the heat exchanger. The tubes are inserted through holes drilled into the tube sheet and are then expanded or welded to ensure a secure attachment.

Naval brass tube sheet produce standard:

Naval brass tube sheets are typically manufactured according to industry standards such as:

1. ASTM B171/B171M - Standard Specification for Copper-Alloy Plate and Sheet for Pressure Vessels, Condensers, and Heat Exchangers

2. ASTM B122/B122M - Standard Specification for Copper-Nickel-Tin Alloy, Copper-Nickel-Zinc Alloy (Nickel Silver), and Copper-Nickel Alloy Plate, Sheet, Strip, and Rolled Bar

3. ASME Boiler and Pressure Vessel Code, Section VIII, Division 1 - Rules for Construction of Pressure Vessels

4. ASME Boiler and Pressure Vessel Code, Section II, Part D - Properties (Material Properties)

These standards provide specifications for the chemical composition, mechanical properties, dimensions, and tolerances of naval brass tube sheets used in various applications such as pressure vessels, condensers, and heat exchangers.

Naval brass tube sheet chemical composition:

Naval brass is a type of brass alloy that is commonly used in marine applications due to its excellent corrosion resistance in seawater.

|

Element |

Composition (%) |

|

Copper (Cu) |

60-63 |

|

Zinc (Zn) |

38-41 |

|

Tin (Sn) |

0.75-1.25 |

|

Lead (Pb) |

0.07 max |

|

Iron (Fe) |

0.10 max |

|

Nickel (Ni) |

0.30 max |

|

Aluminum (Al) |

0.05 max |

|

Silicon (Si) |

0.005 max |

|

Manganese (Mn) |

0.03 max |

|

Others |

0.30 max |

Naval brass tube sheet mechanical properties:

|

Property |

Value |

|

Tensile Strength (MPa) |

380 - 550 |

|

Yield Strength (MPa) |

140 - 460 |

|

Elongation (%) |

10 - 30 |

|

Modulus of Elasticity (GPa) |

110 - 125 |

|

Poissons Ratio |

0.32 - 0.34 |

|

Hardness (Brinell) |

100 - 160 |

|

Impact Strength (J) |

40 - 80 |

|

Fatigue Strength (MPa) |

150 - 320 |

|

Shear Strength (MPa) |

240 - 330 |

The material grade designation for naval brass can vary depending on the standards used. For example, in the United States, naval brass is often designated as C46400 or C46500, depending on the specific alloy composition. In Europe, naval brass is commonly referred to as CuZn39Sn1.

Naval brass tube sheets find applications

1. Marine Heat Exchangers: Naval brass tube sheets are commonly used in marine heat exchangers, which are essential components in ships and offshore structures. These heat exchangers transfer heat between different fluid streams, such as cooling sea water and the fluid circulating in the ships engine or other machinery.

2. Condensers: Naval brass tube sheets are used in seawater condensers, where they help cool and condense hot vapor into liquid form. This process is crucial in various marine and industrial applications, including power generation, refrigeration, and desalination plants.

3. Shell and Tube Heat Exchangers: In industrial applications where heat needs to be transferred between two fluids without mixing them, shell and tube heat exchangers are used. Naval brass tube sheets can be employed in such heat exchangers for their corrosion resistance in seawater environments.

4. Seawater Desalination: Desalination plants use naval brass tube sheets in the heat exchangers and condensers to convert seawater into freshwater by removing salt and impurities through the process of distillation or reverse osmosis.

5. Marine HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems on ships and offshore platforms often incorporate naval brass tube sheets to regulate the temperature of air or fluid circulating within the system.

Naval brass tube sheets in these applications is mainly due to their resistance to corrosion in seawater and their adequate mechanical properties for heat exchanger components. Proper maintenance and monitoring are essential to ensure their longevity and efficient performance in marine environments, where exposure to seawater and harsh conditions can be significant challenges.

Naval brass tube sheet

-

-

Forged Tube Sheets|High-Pressure Forged Stainless Steel Tube Sheets

VIEW MORE+ -

ASTM A182 F51 Tube Sheet|Duplex Stainless Tube Sheet

VIEW MORE+

请输入搜索关键字

确定