U Bend ASTM A209 Alloy Steel Boiler Tube|ASTM A209 T1 Tube

VIEW MORE+- The structure of shell and tube heat exchangers and Main parts

- LL-Foot Finned Tube VS L-Foot Finned Tube

- Whats the process type for helical tube coils?

- Duplex stainless steel knowledge

- Introduce ASTM A209/ASME SA209 T1 Boiler Tube

- Fin-type radiators function and application

- What are the Effects of Heat-Affected Zones in Finned Tubes?

- What Causes Heat-Affected Zones?

- What is the Heat Affected Zone (HAZ) in finned tubes?

- Preheating Before Welding-Method to Prevent Welding Cracks

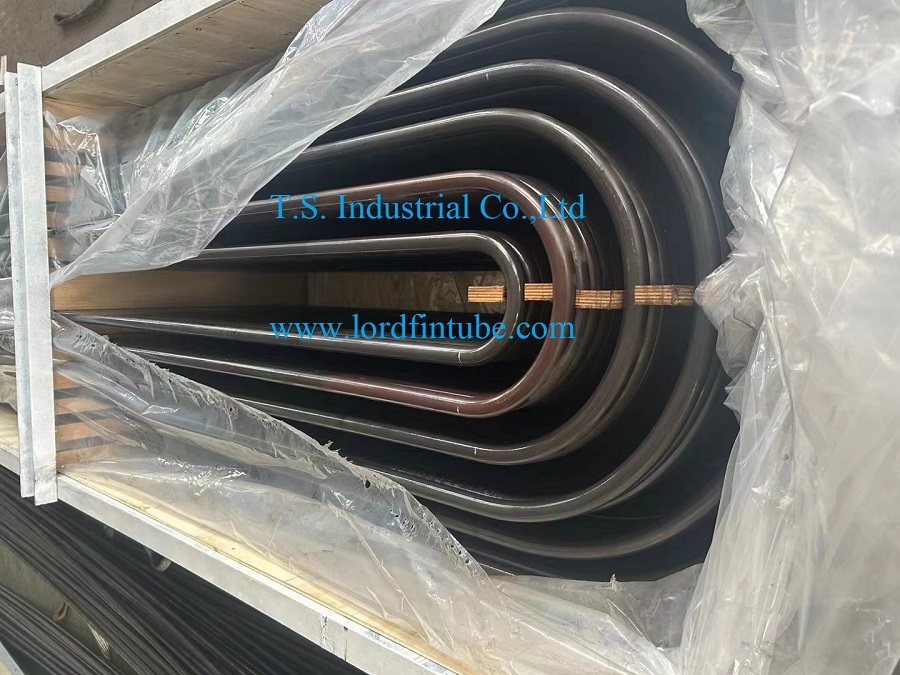

U-bend ASTM A192 Boiler Tubes|U-bend Boiler Tubes

U-bend ASTM A192 boiler tubes are a specific type of heat exchanger tubing made from ASTM A192 specification carbon steel material.These tubes are commonly used in boilers and heat exchangers where efficient heat transfer is crucial.

U-bend ASTM A192 boiler tubes are a specific type of heat exchanger tubing made from ASTM A192 specification carbon steel material. These tubes are commonly used in boilers and heat exchangers where efficient heat transfer is crucial. The "U-bend" in their name refers to the U-shaped configuration of the tube, which allows for improved heat transfer efficiency and reduced thermal stress compared to straight tubes.

1. Common Sizes of U-bend ASTM A192 Boiler Tubes:

- U-bend ASTM A192 boiler tubes come in various sizes, typically ranging from 12.7mm (1/2 inch) to 76.2mm (3 inches) in diameter. The length and bend radius of the U-bend portion can vary depending on the specific application and design requirements.

2. Typical Advantages of U-bend ASTM A192 Boiler Tubes:

- U-bend tubes are designed to facilitate the efficient transfer of heat in boilers and heat exchangers. Some advantages include:

- Improved heat transfer: U-bend design maximizes the contact area between the tube and the fluid, enhancing heat transfer efficiency.

- Space-saving: U-bend tubes save space compared to straight tubes in applications where space is limited.

- Reduced thermal stress: The U-bend shape helps reduce thermal stresses that can occur in straight tubes when subjected to thermal expansion and contraction.

3. Why Use U-bend ASTM A192 Boiler Tubes:

- U-bend tubes are commonly used in boilers and heat exchangers where efficient heat transfer is essential. They are particularly useful in applications with limited space and where minimizing thermal stress is important.

4. U-bend ASTM A192 Boiler Tube Chemical Composition:

- ASTM A192 is a specification for carbon steel boiler tubes. The typical chemical composition of ASTM A192 boiler tubes includes high carbon content (0.06-0.18%), manganese (0.27-0.63%), and trace amounts of phosphorus and sulfur. These tubes are often seamless and designed for high-temperature service.

5. U-bend ASTM A192 Boiler Tube Mechanical Properties:

- The mechanical properties of U-bend ASTM A192 boiler tubes typically meet the requirements outlined in the ASTM A192 specification. This includes properties such as minimum tensile strength, minimum yield strength, and elongation.

6. How to Process U-bend ASTM A192 Boiler Tubes:

- The process of manufacturing U-bend tubes involves bending straight tubes into a U-shaped configuration. The key steps in processing U-bend ASTM A192 boiler tubes include:

- Cutting straight tubes to the required length.

- Heating the tube to the appropriate temperature for bending.

- Bending the tube to the desired radius and angle.

- Cooling and inspecting the U-bend to ensure it meets quality standards.

- If necessary, additional heat treatment and testing may be performed to meet specific requirements.

U-bend ASTM A192 Boiler Tubes

-

-

U-Bend Heat Exchanger Tube

VIEW MORE+ -

U Bend ASTM A214 Tubes|U bend Condenser Tubes

VIEW MORE+

请输入搜索关键字

确定