U Bend ASTM A209 Alloy Steel Boiler Tube|ASTM A209 T1 Tube

VIEW MORE+- The structure of shell and tube heat exchangers and Main parts

- LL-Foot Finned Tube VS L-Foot Finned Tube

- Whats the process type for helical tube coils?

- Duplex stainless steel knowledge

- Introduce ASTM A209/ASME SA209 T1 Boiler Tube

- Fin-type radiators function and application

- What are the Effects of Heat-Affected Zones in Finned Tubes?

- What Causes Heat-Affected Zones?

- What is the Heat Affected Zone (HAZ) in finned tubes?

- Preheating Before Welding-Method to Prevent Welding Cracks

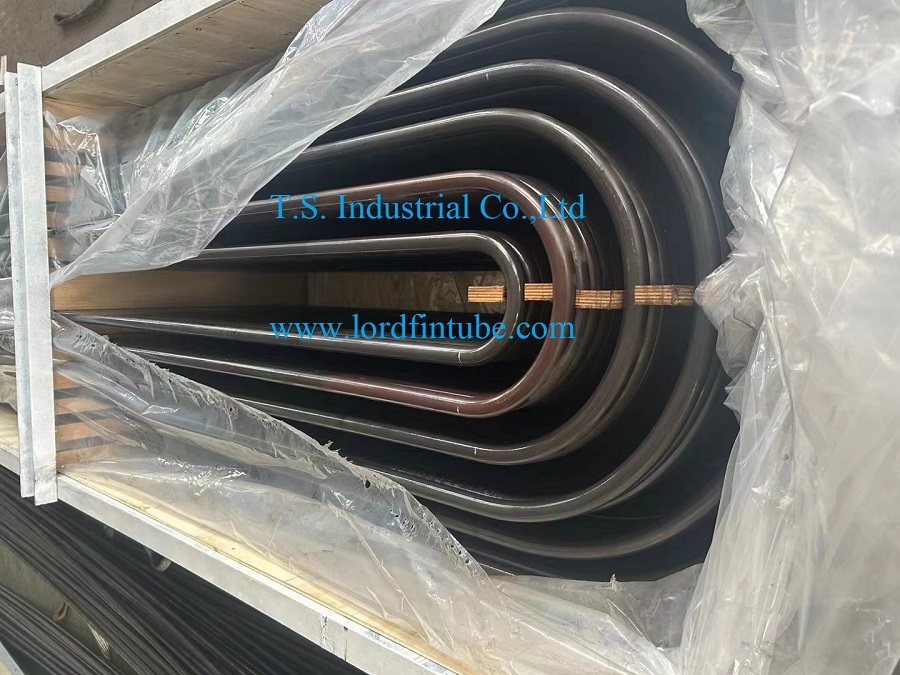

U bend ASTM A213 T22 boiler tube

U bend ASTM A213 T22 boiler tube refers to a type of heat exchanger tube that is made of ASTM A213 T22 alloy steel and has a U-shaped bend in its structure.

What is U bend ASTM A213 T22 boiler tube?

U bend ASTM A213 T22 boiler tube refers to a type of heat exchanger tube that is made of ASTM A213 T22 alloy steel and has a U-shaped bend in its structure. ASTM A213 T22 is a specification for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes. The "U-bend" refers to the shape of the tube, which is bent in the shape of a U.

In the case of a U-bend ASTM A213 T22 boiler tube, the tube is bent to a U-shape and used in a boiler or heat exchanger application where it is necessary to bend the tube for installation or maintenance purposes. The U-bend tube is typically made by heating the straight tube and then bending it around a mandrel to achieve the desired U shape. The tube is then cooled and the ends are prepared for welding.

U-bend ASTM A213 T22 boiler tubes are widely used in various industries including petrochemical, chemical, power generation, and more. They offer excellent resistance to high temperatures, corrosion, and erosion, making them ideal for use in high-pressure, high-temperature applications.

The common sizes of U-bend ASTM A213 T22 boiler tubes

U bend ASTM A213 T22 boiler tube can vary depending on the specific application and requirements. However, some common sizes for these tubes include:

Outer diameter (OD): 1/2 inch to 3 inches

Wall thickness: 0.049 inch to 0.375 inch

Bend radius: 1.5D (where D is the outside diameter of the straight tube)

Length: typically up to 60 feet

Its important to note that these sizes are not exhaustive and that the actual sizes used may vary depending on the specific application and requirements. Its always important to consult the relevant specifications and standards when selecting U-bend ASTM A213 T22 boiler tubes for a particular application.

U bend ASTM A213 T22 boiler tube typical advantage

U-bend ASTM A213 T22 boiler tubes offer several advantages in high-temperature, high-pressure applications, including:

1. High-temperature strength: The alloy steel used in these tubes provides excellent strength and resistance to high temperatures, making them ideal for use in boiler and heat exchanger applications.

2. Corrosion resistance: The alloy composition of ASTM A213 T22 tubes includes chromium and molybdenum, which provide excellent corrosion resistance in harsh environments.

3. Erosion resistance: The high hardness and toughness of the tubes make them resistant to erosion caused by abrasive materials, which is essential in high-pressure applications.

4. Improved flow characteristics: The U-bend shape of the tubes can improve flow characteristics, resulting in better efficiency in heat transfer applications.

5. Easy installation and maintenance: The U-bend shape of the tubes makes them easy to install and remove, which is essential for maintenance and repair purposes.

Overall, U-bend ASTM A213 T22 boiler tubes offer excellent performance in high-temperature, high-pressure applications, making them a popular choice in industries such as power generation, chemical processing, and petrochemical refining.

Why use U bend ASTM A213 T22 boiler tube?

The U-bend shape is used for ASTM A213 T22 boiler tubes for several reasons:

1. Space-saving: The U-bend shape allows for a more compact design of boilers and heat exchangers, as the tubes can be bent to fit in a smaller space.

2. Improved flow characteristics: The U-bend shape can improve flow characteristics by reducing pressure drop and turbulence, resulting in better efficiency in heat transfer applications.

3. Thermal expansion: U-bend shape accommodates for thermal expansion and contraction of the tubes without causing damage to the system.

4. Maintenance and repair: The U-bend shape makes it easier to install and remove the tubes during maintenance and repair, as it can be manipulated to fit in tight spaces and around other components.

Overall, the U-bend shape of ASTM A213 T22 boiler tubes provides several advantages, including improved efficiency, space-saving, and easier maintenance and repair, which makes them an ideal choice for high-temperature, high-pressure applications in various industries.

U bend ASTM A213 T22 boiler tube chemical composition:

The chemical composition of ASTM A213 T22 seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes is as follows:

|

ASTM A213 T22 Chemical Composition (W.T.%) |

|||||||

|

Elements |

C |

Mn |

P |

S |

Si |

Cr |

Mo |

|

Standard Requirement |

0.05-0.15 |

0.3-0.6 |

≤0.025 |

≤0.025 |

≤0.5 |

1.9-2.6 |

0.87-1.13 |

The combination of these elements provides excellent mechanical properties and high-temperature strength, making ASTM A213 T22 tubes suitable for use in high-pressure, high-temperature applications such as boilers, heat exchangers, and superheaters in power generation and petrochemical industries.

U bend ASTM A213 T22 boiler tube mechanical property:

The mechanical properties of ASTM A213 T22 seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes are as follows:

Tensile strength: The minimum tensile strength of the tubes shall be 415 MPa (60 ksi).

Yield strength: The minimum yield strength of the tubes shall be 205 MPa (30 ksi).

Elongation: The minimum elongation of the tubes shall be 30%.

Hardness: The maximum hardness of the tubes shall be 163 HBW (88 HRB).

These mechanical properties ensure that the tubes have excellent strength and toughness at high temperatures, making them suitable for use in high-pressure, high-temperature applications such as boilers, heat exchangers, and superheaters in power generation and petrochemical industries. Its important to note that these mechanical properties are minimum values, and actual values may vary depending on the specific manufacturing process and testing requirements.

How to process U bend ASTM A213 T22 boiler tube?

The process of making U-bend ASTM A213 T22 boiler tubes involves several steps, including:

1. Straightening: The straight tubes are first cut to the desired length and then straightened using specialized equipment to ensure they are perfectly straight.

2. Bending: The straight tubes are then placed in a U-bending machine, where they are bent to the desired shape with a mandrel inserted inside to prevent buckling or wrinkling of the tube walls.

3. Heat treatment: After bending, the U-bent tubes are heat-treated to ensure they retain their shape and mechanical properties.

4. Flattening and testing: The U-bent tubes are then flattened to ensure there is no cracking or buckling, and various non-destructive testing methods are performed to ensure the tubes meet the required standards and specifications.

5. Cleaning and finishing: The U-bent tubes are then cleaned and finished to remove any dirt or debris, and they are ready for installation.

6. Packing: Multiple tubes are then bundled together, usually in a wooden crate or box, and secured with steel strapping or bands to prevent any movement or shifting during transportation.

Its important to note that the process of making U-bend ASTM A213 T22 boiler tubes requires specialized equipment and expertise, and should only be performed by qualified professionals. Any deviations from the standard process or quality control measures can result in compromised tube quality and performance.

U bend ASTM A213 T22 boiler tube

-

-

U-Bend Heat Exchanger Tube

VIEW MORE+ -

U Bend ASTM A214 Tubes|U bend Condenser Tubes

VIEW MORE+

请输入搜索关键字

确定