U Bend ASTM A209 Alloy Steel Boiler Tube|ASTM A209 T1 Tube

VIEW MORE+- The structure of shell and tube heat exchangers and Main parts

- LL-Foot Finned Tube VS L-Foot Finned Tube

- Whats the process type for helical tube coils?

- Duplex stainless steel knowledge

- Introduce ASTM A209/ASME SA209 T1 Boiler Tube

- Fin-type radiators function and application

- What are the Effects of Heat-Affected Zones in Finned Tubes?

- What Causes Heat-Affected Zones?

- What is the Heat Affected Zone (HAZ) in finned tubes?

- Preheating Before Welding-Method to Prevent Welding Cracks

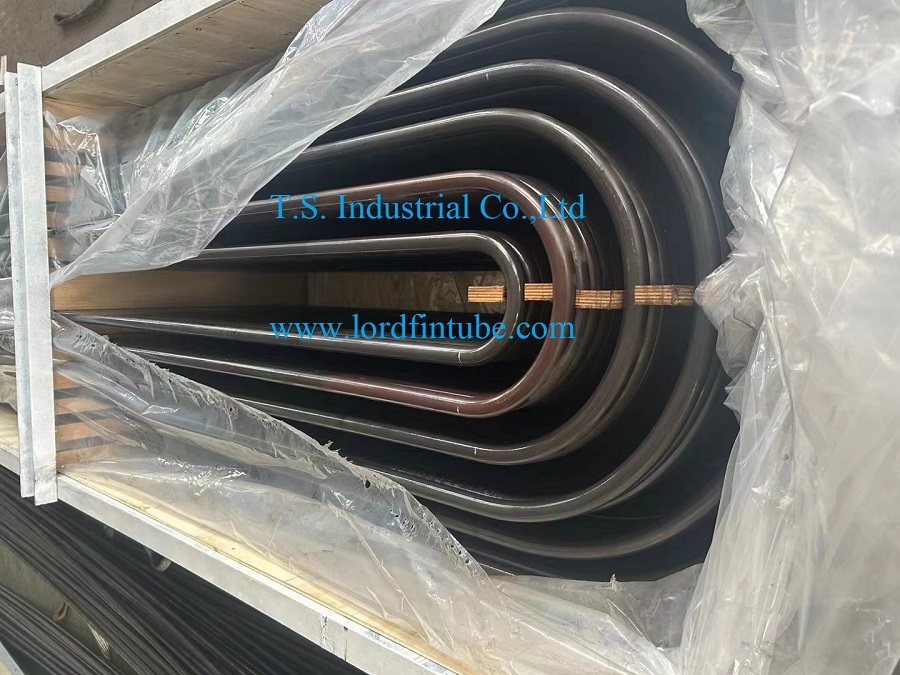

U Bend ASTM A268 TP405 Tube|Martensitic Stainless Steel Tube S40500

Martensitic stainless steel tube as per ASTM A268 TP405 (S40500) is a standard specification for seamless and welded ferritic and martensitic stainless steel tubes for general corrosion-resisting and high-temperature service.

What is Martensitic stainless steel tube S40500?

Martensitic stainless steel tube as per ASTM A268 TP405 (S40500) is a standard specification for seamless and welded ferritic and martensitic stainless steel tubes for general corrosion-resisting and high-temperature service. This specification covers tubes in sizes ranging from 1/8 inch to 3 inches in outside diameter and from 0.015 inch to 0.320 inch in wall thickness.

TP 405 is a low carbon, 12% chrome steel, not subject to appreciable hardening through air cooling from high temperatures. This tendency retards the formation of hardening cracks caused by welding. Practically the same corrosion and oxidation resistance as TP410. Can be machined, drawn, spun and formed without difficulty. Used for applications where hardening upon cooling from high temperatures must be avoided. Has excellent long-time stability up to 1200°F.

Martensitic stainless steels are a type of stainless steel that contains high levels of chromium and carbon, and lower levels of nickel. They are known for their hardness, strength, and wear resistance, and are often used in applications that require these properties, such as cutlery, knives, and surgical instruments.

Martensitic stainless steel tube S40500 Chemical composition mass in %

The ASTM A268 TP405 Tube grade of martensitic stainless steel is specifically designed to offer good corrosion resistance, high strength, and good oxidation resistance in high-temperature environments. It contains 12-14% chromium and 0.03% carbon, as well as small amounts of other elements such as manganese, silicon, and sulfur.

|

Element |

Minimum (%) |

Maximum (%) |

|

Carbon |

0.08 |

0.15 |

|

Manganese |

- |

1 |

|

Phosphorus |

- |

0.04 |

|

Sulfur |

- |

0.03 |

|

Silicon |

- |

1 |

|

Chromium |

11.5 |

14.5 |

|

Nickel |

- |

0.5 |

|

Material grade |

Norm |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Ti |

others |

|

1.4002 |

EN 10297-2 |

0,080 |

1,00 |

1,00 |

0,040 |

0,030 |

12,00 - 14,00 |

Al 0,1 – 0,3 |

|||

|

TP405 |

ASME SA / ASTM A 268 |

0,080 |

1,00 |

1,00 |

0,040 |

0,030 |

11,50 - 14,50 |

0,50 |

Al 0,1 – 0,3 |

Martensitic stainless steel tube S40500 Mechanical properties and heat treatment

|

Property |

Value |

|

Density |

7.75 g/cm³ |

|

Melting Range |

1390-1450°C |

|

Modulus of Elasticity |

200 GPa |

|

Electrical Resistivity |

0.60 μΩm |

|

Thermal Conductivity |

21 W/mK |

|

Material grade |

Norm |

Rp 0,2 MPa min. |

Rp 1,0 MPa min. |

Rm MPa min. max. |

A |

Hardness HRB max. |

Heat treatment |

|

1.4002 |

EN 10297-2 |

210 |

220 |

400 |

10 |

annealed |

|

|

TP405 |

ASME SA / ASTM A268 |

205 |

415 |

20 |

95 |

annealed |

Rp 0,2 = Rotation; Rp 1,0 = Yield Strength; Rm = Tensile Strength; A = Elongation

Martensitic stainless steel tube S40500 Advantages:

1. High strength and hardness

2. Good corrosion resistance in mild environments

3. Good oxidation resistance at high temperatures

4. Good wear resistance

5. Easily machinable and weldable

Martensitic stainless steel tube S40500 Typical Usages:

1. Boiler tubes and superheater tubes in power generation plants

2. Heat exchanger tubes in chemical processing plants

3. Automotive exhaust systems

4. Aircraft components

5. Surgical and dental instruments

6. Cutlery and kitchen knives

ASTM A268 TP405 Tube

-

-

U-Bend Heat Exchanger Tube

VIEW MORE+ -

U Bend ASTM A214 Tubes|U bend Condenser Tubes

VIEW MORE+

请输入搜索关键字

确定